The metal casting business is continually evolving, pushed via the demand from customers for greater precision, enhanced good quality, and diminished defects. Within this landscape, the tension casting machine performs a vital position. having said that, for essentially the most demanding programs, a specialised type of casting device is needed: the vacuum pressure casting machine. this information explores the exclusive benefits get more info of these machines, concentrating on how they greatly enhance the precision and quality of metal casting, specifically for important metals like gold and platinum.

Table of contents:

some great benefits of utilizing Vacuum Pressure Casting equipment for prime-high quality Results

How Vacuum tension Casting Enhances the Accuracy of Gold, Platinum, and Other Metals

Why Vacuum stress Casting is important for large-Precision Industries

The Advantages of utilizing Vacuum force Casting equipment for High-good quality effects

Vacuum stress casting equipment give a major breakthrough when compared to regular casting methods. The core profit lies during the elimination of air pockets and fuel porosity throughout the casting. By executing the casting process less than a vacuum, the molten metallic is permitted to movement extra freely and totally fill the mould cavity. This ends in denser, more powerful castings with less internal defects. On top of that, the appliance of strain during the solidification section helps to additional consolidate the steel, minimizing shrinkage and improving upon the overall high quality. This can make vacuum strain casting ideal for producing intricate and sophisticated styles wherever even the smallest imperfections can compromise the operation or aesthetic enchantment of the ultimate merchandise.

How Vacuum Pressure Casting boosts the Accuracy of Gold, Platinum, as well as other Metals

The substantial price and distinctive Houses of valuable metals like gold and platinum necessitate Outstanding casting precision. Vacuum gold casting equipment technologies is especially created to fulfill these demanding requirements. The vacuum natural environment not merely stops oxidation in the molten metal but additionally makes sure a clear and reliable casting system. This is especially essential for gold, which can easily tarnish or acquire floor defects if exposed to air throughout casting. Also, the managed force used through solidification promotes uniform grain structure and minimizes the chance of cracking or distortion. This results in castings that happen to be dimensionally correct, have exceptional floor end, and keep the desired mechanical Qualities.

Why Vacuum force Casting is Essential for High-Precision Industries

higher-precision industries, for instance aerospace, clinical device production, and large-stop jewellery generation, rely on vacuum force casting to attain the stringent excellent criteria essential for his or her programs. the opportunity to develop castings with tight tolerances, negligible defects, and regular substance Houses is paramount in these sectors. one example is, from the aerospace field, vacuum stress Forged elements are Utilized in vital motor areas exactly where dependability and efficiency are non-negotiable. likewise, in health care device production, vacuum tension casting guarantees the biocompatibility and structural integrity of implants. The benefits lengthen to jewelry building in addition, the place intricate styles and flawless finishes are essential for developing large-worth items. eventually, vacuum force casting offers the required Manage and precision to meet the demanding prerequisites of such industries. As evidenced by products like the TAKJ-VC-W offered at https://taeantech.com/products/takj-vc-w, these equipment are precisely created to cater towards the precision desired by vacuum pressure casting procedures.

In summary, vacuum strain casting devices are indispensable tools for obtaining superior precision and remarkable excellent in metallic casting. The mix of vacuum environment and managed stress eradicates common casting defects, enhances material Qualities, and makes sure dimensional accuracy. For industries demanding the best levels of functionality and dependability, purchasing vacuum stress casting technology is not only a decision but a necessity. take into account the distinct requirements of the application and investigate the different vacuum tension casting remedies accessible to unlock new options in metal casting and elevate the standard of your ultimate goods.

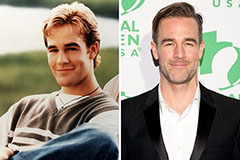

James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!